Robotics

Automation

Fast, easy, efficient with the

Robot Cell System

Robot Cell System

at Work

at Work

Use Case Videos

FLEXIBLE SOLUTIONS FOR THE AUTOMATION OF HANDLING PROCESSES

Consulting and sales

- Standard solutions for feeding of parts to machine tools

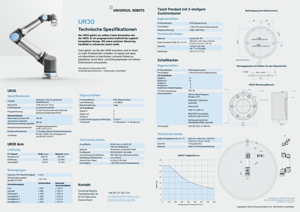

- Use of lightweight robots from Universal Robots

- A selection of pre-engineered modules for feeding and depositing your parts

- Advice on the selection of accessories such as finger grippers, suction pads, cameras, etc. .

Conception and construction

- Procurement of the components

- On-site commissioning

- Technical documentation

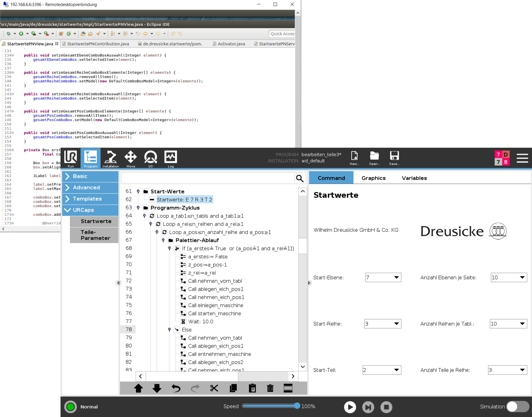

Individual programming solutions

- Individual programming solutions

- URCaps: Design and implementation of individualized control elements and input options for the Universal Robots Polyscope interface

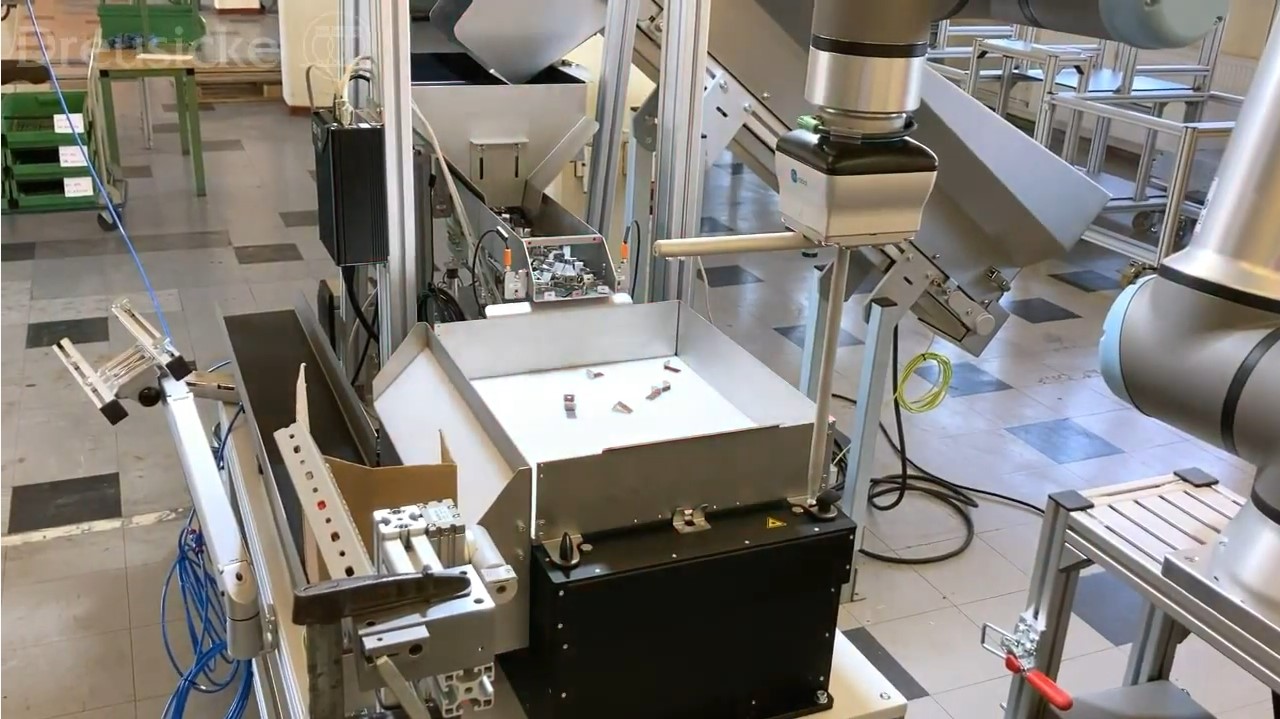

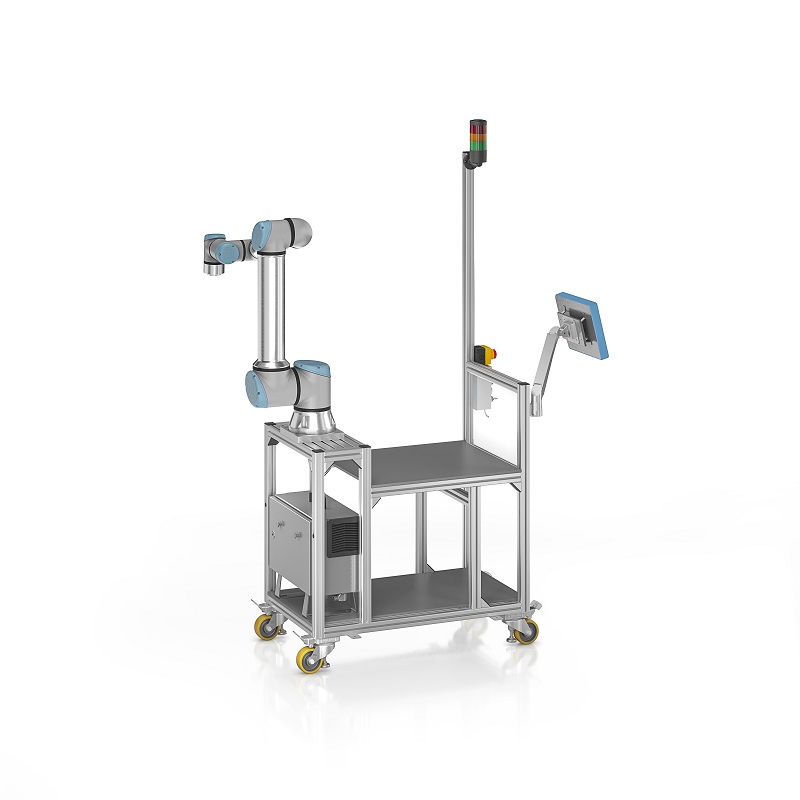

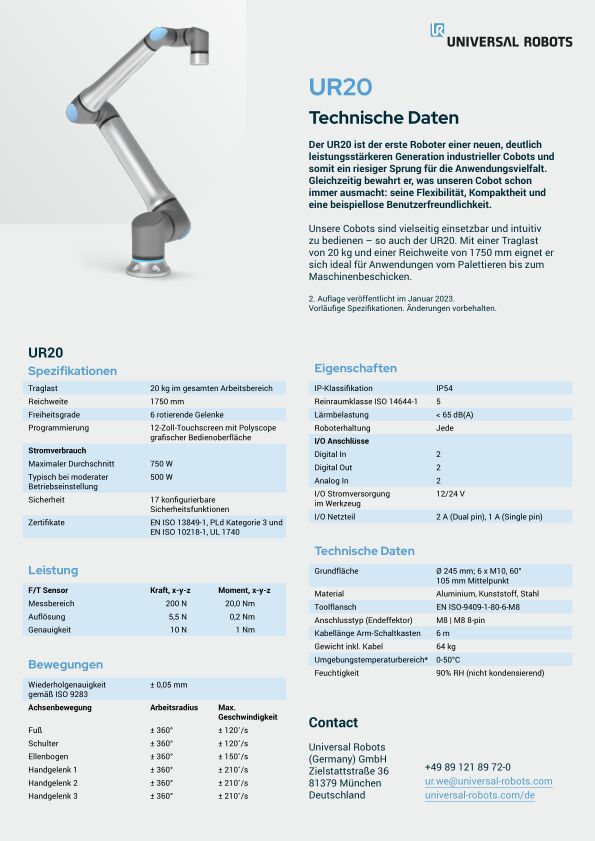

DREUSICKE ROBOT CELLS FOR MACHINE LOADING AND UNLOADING

Get a complete solution with our robot cells:

This includes a robot from Universal Robots fully integrated in a cell consisting of a table, workpiece magazines / parts feeding solutions and the necessary safety devices. Simple transfer from one workstation to the next. Our robot cells are mobile by means of lifting rollers with integrated locking feet. Well suited for use on CNC-machine tools as well as on older machines such as conventional lathes, milling or punching machines, or measuring devices. The gripper of the robot takes over the manual operation of the machine. Thus, no direct connection between the robot and the machine is necessary.

BENEFIT FROM LIGHTWEIGHT ROBOTS

Lightweight robots from Universal Robots

They are easy to get started with, precise and suitable for various tasks.

Usable in 'Cobot-mode' - in coexistence or collaboration with personnel.

Simple operation and program guidance

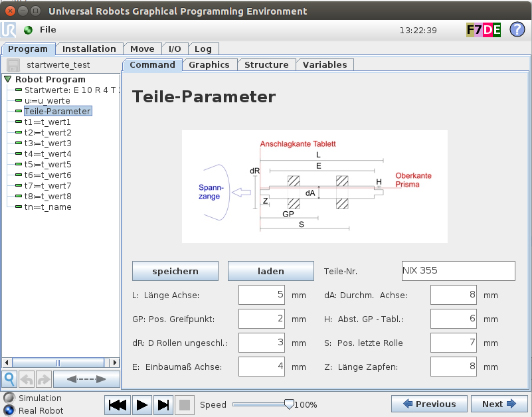

The advantage of our solution is the fast and user-friendly conversion of the robot cell settings for picking and placing different parts of your production range.

During the design of the robot cell control features, we put special emphasis on the importance of a simple user guidance.

Here, we continuously profit from experience gained from own applications in our production of technical rubber rollers.

Program guidance as familiar from CNC programming.

Your employees do not have to become robot specialists.

You control the insertion and removal processes simply by entering parameters such as drawing dimensions and position corrections.

Just like programming CNC machine tools.

Flexible program management

Individual parameter packages, such as dimensions of the part, the sizes of boxes or trays containing the parts, or the necessary positions during the insertion process on the machine, can be saved and reloaded separately from each other. To change over the settings to a new part on the same machine, you simply load the corresponding part parameters and can then concentrate on setting up the machine.

Fast amortization

This makes the automation of work processes reasonable and affordable, even for small and medium-sized series. Due to the fast integration and a versatile applicability in your production, this investment often pays for itself within one year.

AUTOMATION – GET STARTED THE EASY WAY.

Cobots from Universal Robots fit perfectly to this slogan. Easy to program, superior design and precision in positioning and repeat accuracy are only a few of their features.

To these add a wide selection of plug & play accessories – software and hardware.

The best example are the components of our VARiTEND robot cell system.

They lead you the way to an easy start of a successful automation project.

Dreusicke is Certified System Integrator

of Universal Robots.